Sharpening Scandinavian Knives

These knives are exceptionally easy to sharpen freehand. The wide bevel is simply laid flat to the stone when sharpening. You want to remove metal from the entire width of the bevel to preserve the correct angle. You are removing more metal this way, but it doesn't really take a lot longer because you can bear down harder without fear of losing the correct angle. Because the angle is preserved through successive sharpenings, you, your son, and grandson, will never have to regrind the blade to restore the profile!

It's best to be sure your stones are really flat. After using them a while, they tend to wear in the center, and become saddle shaped. Stones can be flattened by working two similar stones together, by working them on a sheet of emery cloth laid on plate glass, or with a special ceramic flattening plate and paste used in Japan. Or you can just use diamond plates instread of stones. Diamond plates cut faster and stay flat. They are used with water rather than messy oil, and can even be used dry in a pinch. I've had a thin diamond plate, about the size of a credit card, in my wallet for years. I've backed it with a scrap of worn 9-micron abrasive film for a strop. It's all I really need to maintain my knives indefinitely.

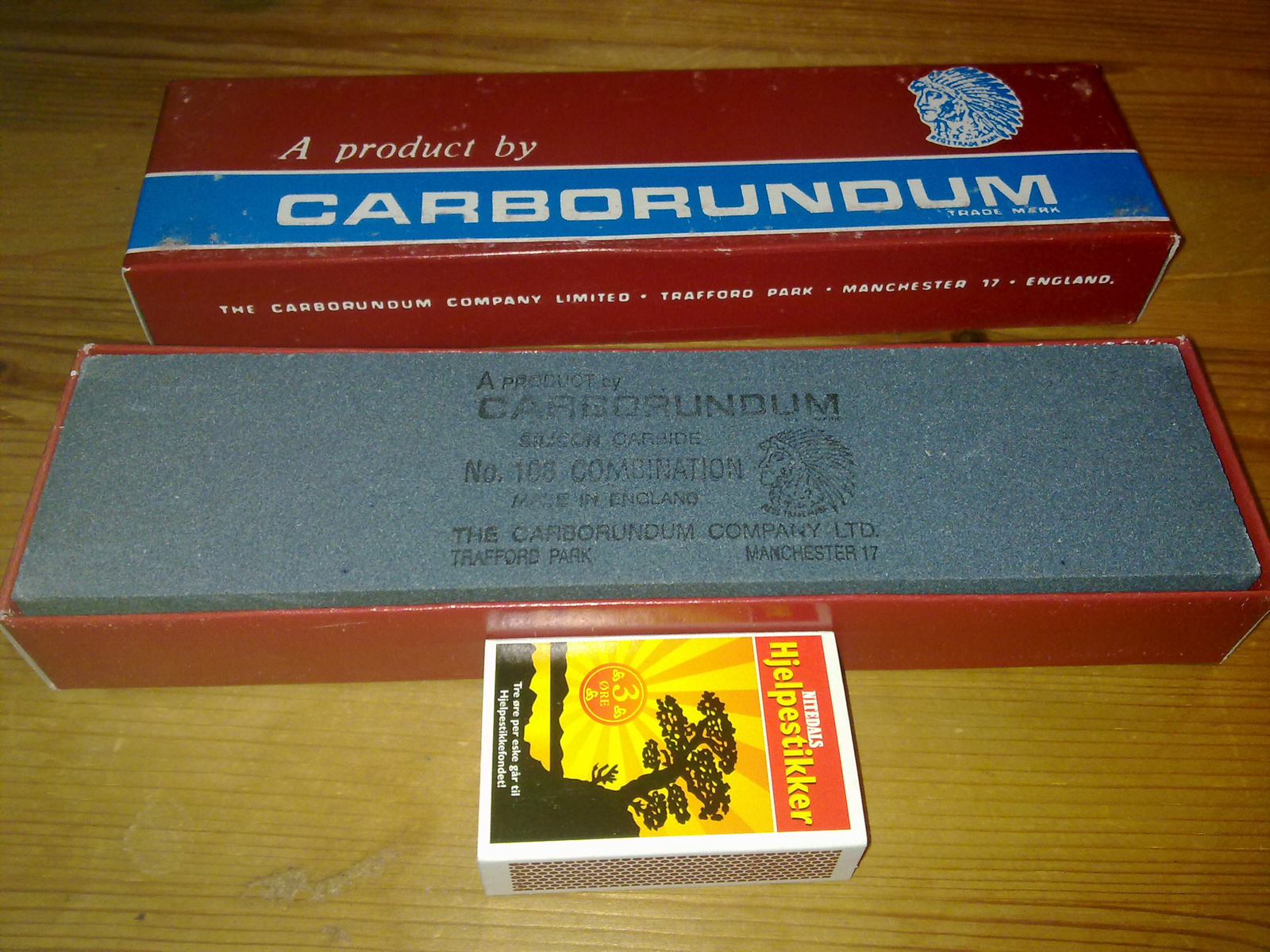

To sharpen, press the bevel flat to the stone and work the entire edge. In the beginning, I don't think it matters what type of motion you use, as long as you keep the bevel flat. Work it until you can feel a slight burr when you run your finger tip off the edge on the other side. You want this all along the edge. When you have established a burr along the entire length of the edge, turn the knife over and repeat on the other side. When you can feel the burr all along the first side, you've established the edge. Now you want to remove the burr. Stroke the blade lightly over the stone as if you were taking slices off the surface. At this point you want to move in one direction only, edge first, as if you were cutting the stone. Keep the bevel flat. Switch from side to side, moving the burr back and forth, until it's honed away. Moving the blade diagonally gives the effect of a slightly finer stone. Finish on a strop. If your blade is very dull, or badly nicked, you might want to start with a medium, or even coarse, stone to remove the nicks. Then move to the fine stone. Depending on your use, you may want to repeat with successively finer grades of stones or diamond plates. For the best possible results you can go down to a mirror finish, but this is overkill for most purposes.

This applies to knives used for woodcarving or other work requiring the finest possible edge. For general use many folks like to strengthen the edge with a micro bevel. Just lift the blade very slightly on your finest stone, and take a few light strokes to establish a small secondary bevel. A better way to do this is to use a super fine abrasive paper (7 or 15 micron, or about 1200 grit) on a semi-soft surface like a magazine or newspaper. This is really just an aggressive strop, and blends the micro bevel smoothly into the primary bevel. You can also use a razor strop,

The book "Swedish Carving Techniques" by Wille Sundqvist has a good section on this style of blade and sharpening. It's a good book and worth having. Sadly, it's gone out of print, but you can probably find a copy at your library, or one of the used book services.

I avoid using power grinders on these knives. It's really easy to overheat the thin edge, and ruin the temper. It's really hard to keep the bevel truly flat. With the fast cutting diamond plates, it's easier to do it by hand. There's also a satisfaction in sharpening by hand you don't get with power equipment. I find it a pleasant way to relax.

| Gyártó: |

Nokia N97

|

| Fókusztáv: |

5.4mm

|

| Rekesz: |

f/2.8 |

| Zársebesség: |

1/33

|

| ISO: |

200 |

| Készült: |

2010. aug. 19. 17:57

|